“Safety in the workplace.”

It’s a mantra that every business should follow, particularly in industrial settings. Worker safety must be a priority for every safety manager and maintenance manager.

In fact, it’s more than a priority. In many countries, it’s a directive and compliance issue. In the United States, industries are regulated by the Occupational Safety and Health Administration (OSHA). Many sections of 29 CFR 1910 cover the handling of workplace hazards.

The Canadian equivalent, the Canadian Centre for Occupational Health and Safety (CCOHS) has similar information about Canadian regulations for the control of workers’ safety in industrial environments.

Safe Work Australia is an Australian government statutory body established to develop national policy relating to work health and safety.

Studies have shown that the leading cause of accidents and injuries in the workplace is human error, with 80 percent of workplace accidents ultimately caused by the worker.

Can anything be done to lessen the risks?

Hazard control methods — 4 approaches

According to the Canadian OSH fact sheet, there are four main ways to control a hazard:

- Elimination of the hazard by removing or substituting the hazard.

- Engineering controls, including redesigns or modifications.

- Administrative controls that control the way work is done.

- Personal Protective Equipment (PPE) worn by individuals.

Of the four, administrative controls and PPE are very common forms of hazard control, particularly in already established plants and factories. While they are effective in most cases, there are still issues.

For instance, even the best-formulated administrative standard operating procedures ultimately rely on worker cooperation.

PPE control measures, while effective, can often present new potential hazards as well. For example, performing lighting maintenance in elevated locations requires the use of fall arrest equipment such as harnesses, lanyards and certified tie-off points.

Even though this equipment will keep the worker from falling to the ground, there are additional considerations. The ongoing cost of equipment maintenance, repair and replacement adds to the investment required for PPE.

The top methods of hazard control

Of the two remaining options, elimination of the hazard is the most desirable. If the hazard can be removed or a suitable, safe substitute used, then a safe work environment is achieved.

However, this is not always possible, particularly when using process chemicals or gases. Other situations — such as lighting requirements for safety and productivity — often involve light fixtures located in hard to reach, potentially dangerous locations, involving working at heights.

All things considered, engineering controls are often the best, if not the only solution to hazardous tasks and environments. And while engineering controls implemented at initial construction are best, retrofits allow for hazard abatement in older or already constructed facilities.

The potential hazards of lighting maintenance

Industrial lighting maintenance is far more complex than just screwing in a light bulb. In many cases, the location of the light fixture alone presents hazards beyond that of general lighting.

Outdoor pole lighting presents additional challenges. Dust, smoke film, oil and dirt accumulate on the reflective surfaces of fixtures, lenses and lamps, requiring regular cleaning to avoid luminaire dirt depreciation. Damage from adverse weather conditions may require the replacement of lens and luminaire components.

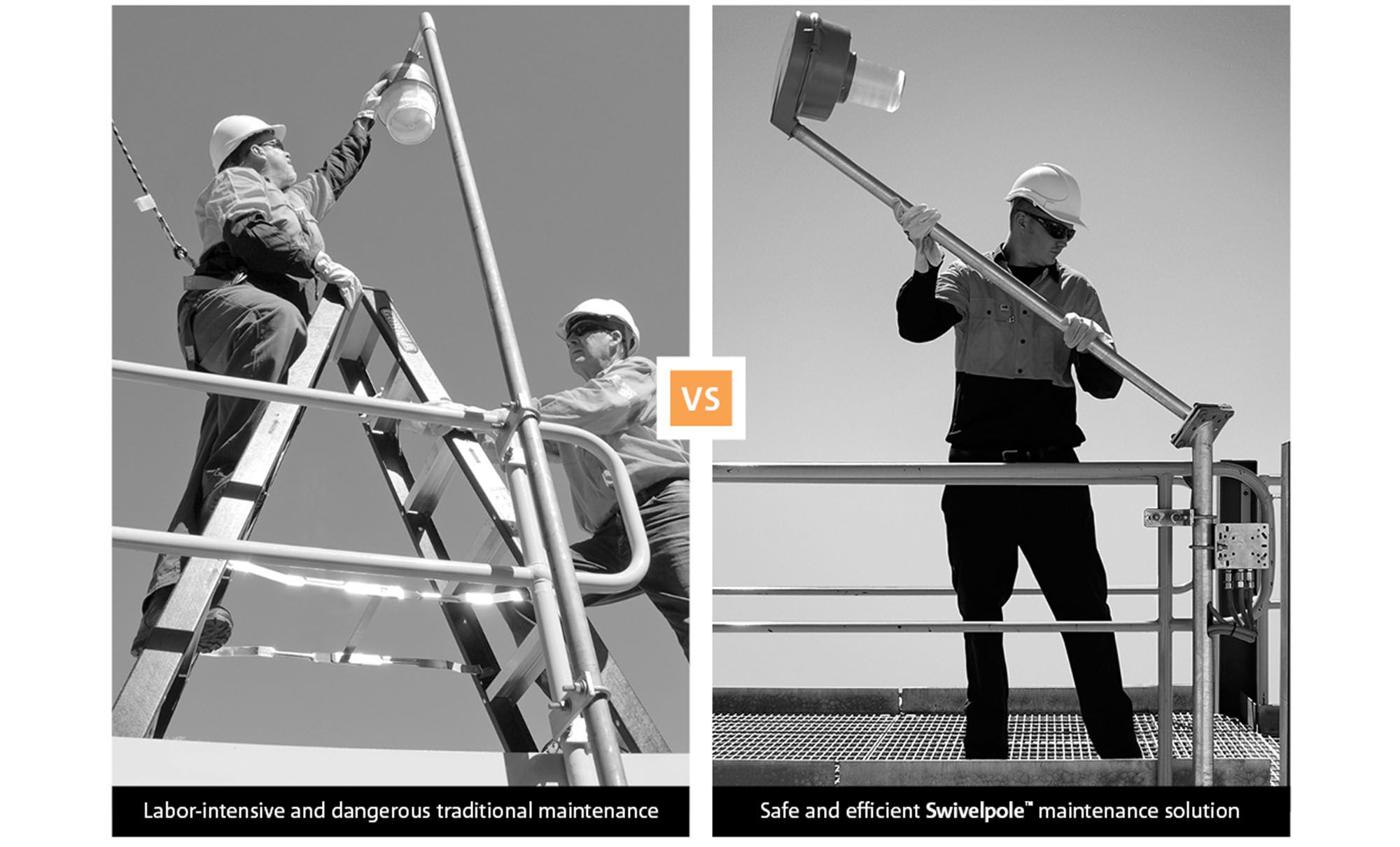

Work performed on elevated catwalks presents the potential for trips and falls. Bulb and ballast replacement often require the use of fall protection restraints and certified tie-off points.

Safety harnesses, carabiners, fixed and retractable lanyards, and Dee-rings require routine, documented inspections. Since wind gusts are unpredictable, the maintenance worker must be adequately protected in every situation. Often a second worker must be present to ensure a safe work environment is maintained.

In recent years, engineering controls have been developed for safer and often more convenient lighting maintenance task completion. The easier and safer a task is to accomplish, the more often it will be done.

Innovative solutions include options that lower the light fixture to the worker instead of raising the worker to the light fixture.

During your next job safety analysis, evaluate lighting maintenance tasks for potential hazards. If necessary, develop a plan to manage the risk of trips, falls and injury. Worker safety is not just a compliance issue — it’s your responsibility.

The Swivelpole™ lowering pole solution is recognised globally for providing simple, fast and affordable access to light fixtures and equipment. The innovative access solutions eliminate the risk of working at heights, through the controlled lowering of light fixtures and equipment to a safe and comfortable working position.

Maxis™ is the next generation lowering pole solution for safely accessing light fixtures and equipment.