Planned maintenance programs are standard practices in nearly every industrial manufacturing environment. Also called preventive maintenance schedules, they save companies considerable money when designed and carried out properly.

Everything from bearings to light bulbs carries an expected longevity. These preventive measures ensure that parts are replaced before they fail. Waiting to replace a part until it fails is costly. Downtime and its associated costs are often expensive.

However, routine lighting maintenance is often overseen, and bulbs are not replaced until they fail. This sporadic maintenance strategy is counterproductive and often carries hidden costs. Group relamping can save significant amounts, according to studies done at the Oklahoma State University.

How group relamping saves money

Every lamp has a specified “average life,” measured in hours. The specification is found on the bulb’s packaging or from manufacturer data sheets. The average life is usually calculated as the point where 50% of test bulbs have burned out.

Bulbs start to lose their intensity when they are first energized. The lumen drop is shown in graph form on the packaging. Often, the intensity falls below acceptable levels long before failure.

Using the charts, an optimal time for bulb replacement can be calculated. Many planners use the 70% of average life for a standard. Intensity is usually at or above acceptable standards. However, the lamp is nearing the end of its life cycle and the potential for failure increases.

Bulbs in an area may not fail at the same time, even if installed at the same time. By relamping a group of bulbs, you lessen the chance of both individual failure and the expense involved in replacing an individual lamp. There are several ways that group relamping saves money.

- Lamp replacement can be scheduled during downtime, eliminating the impact on production.

- Replacing lamps as a group can decrease the costs involved, particularly in locations where the access equipment necessary must be rented. This includes scaffolding, scissor lifts and boom lifts.

- Since much of the cost in bulb replacement includes the initial setting up and final breaking down of maintenance equipment — scaffolding, ladders, etc. — the labor costs involved can be reduced.

According to the calculations of the Oklahoma State University report, the savings can be substantial. They calculated the potential savings using 229 lamps per year in spot relamping vs 1,600 lamps over 5 years in group relamping.

According to their calculations, group relamping could save almost $5,000 over spot relamping during a 5-year period.

Additionally, fixture maintenance can be scheduled during a group relamping task. Cleaning of the fixture and lenses can be done easily since the necessary equipment is on hand.

Consider all access options available for maximized return on investment

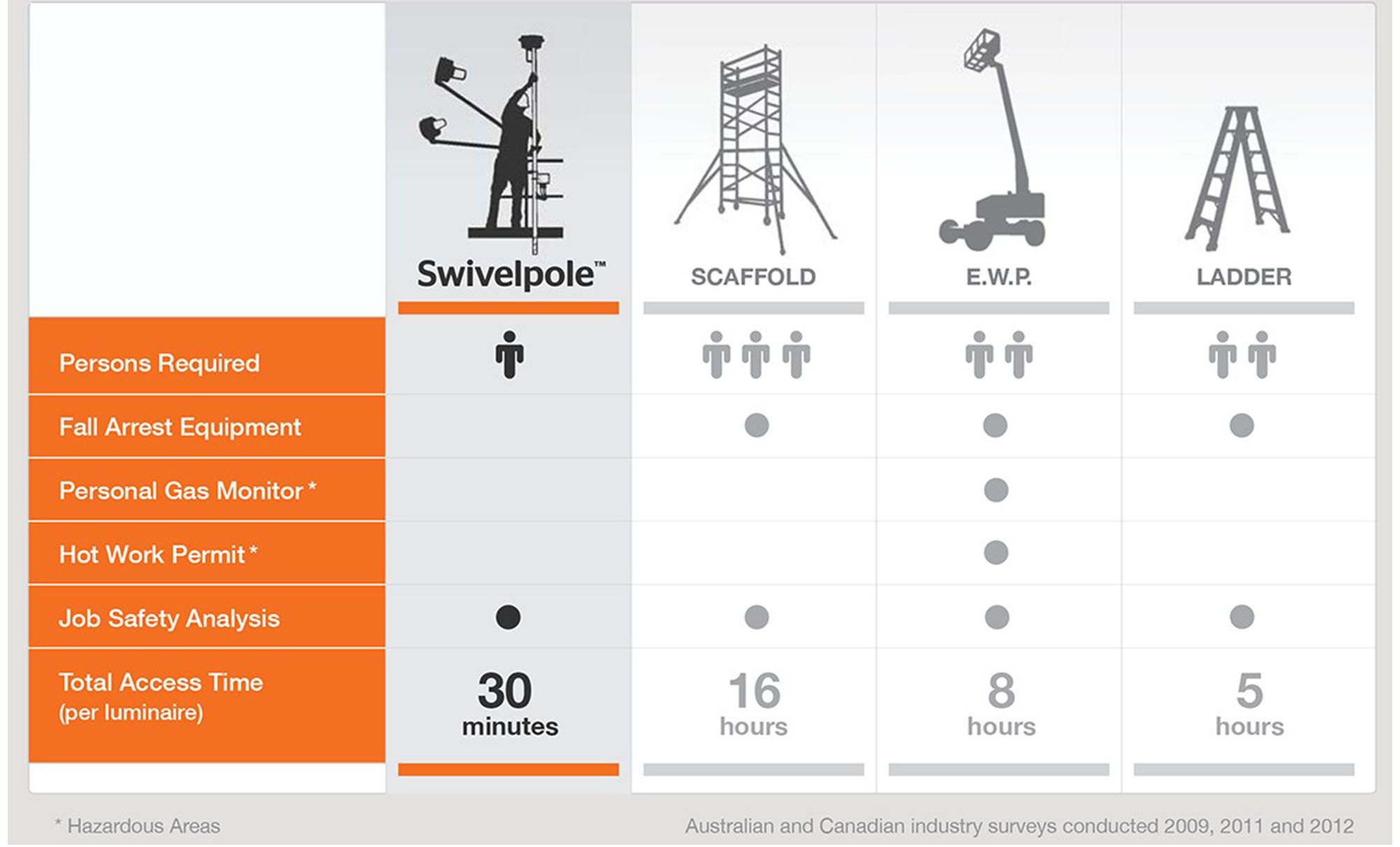

You can streamline your routine lighting maintenance, making it more efficient, cost effective and safe. This chart compares four access options available.

For many installations, both new and retrofitted, there are lowering systems available that allow easy access to fixtures and equipment for inspection, maintenance and upgrades.

Using systems that allow light fixtures to be lowered to the worker manually without the need for lifts and scaffolding reduces labor cost and cost associate with access equipment hire, resulting in significant savings over the lifecycle of a plant.

The Swivelpole™ lowering pole solution is recognised globally for providing simple, fast and affordable access to light fixtures and equipment. The innovative access solutions eliminate the risk of working at heights, through the controlled lowering of light fixtures and equipment to a safe and comfortable working position.

Maxis™ is the next generation lowering pole solution for safely accessing light fixtures and equipment.